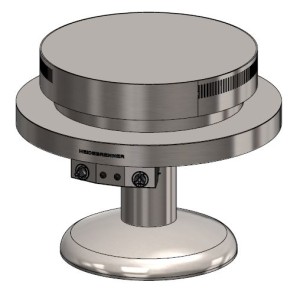

Description

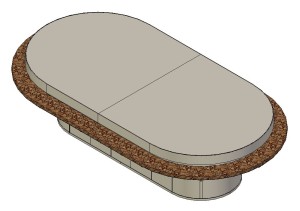

Electric Mongolian grill "ALTAI"

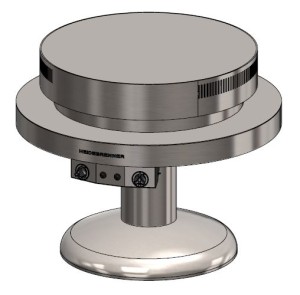

Outer dimensions with plate rack: Ø 2200 x 1100 x 1000 mm,

Oval grilling surface Ø 1400 x 800mm

3 heating zones each P=9.5 kW, rated power P=28.5 kW, U=400V 3 ~

Connection cable: 3x CEE16A

Solid steel top plate made of special heat-resistant steel: 30mm material thickness, tubular heating element cast in a 20mm aluminum core. Lowered fat collection channel in the front working area, slope to the sides. Conveniently removable grease collection containers (GN containers) in the non-visible area. Plate shelf 150 mm wide made of CNS.

Each heating zone acts independently, which guarantees increased reliability. In the event of an error, you can always work on two heating zones without restrictions. Electronic microstats guarantee the highest temperature precision. The temperature range (working range) of the three heating zones can also be subsequently adjusted to the local needs of the cook. If the menu changes, the needs often change as well. The adjustments are made by hand app, no technical adjustments are required.

Each tubular heating element is electrically controlled individually and autonomously via a temperature sensor. This principle maximizes the temperature precision in the area. A digital display makes it easier to read and set the desired setpoint temperature. Error messages are also shown on the said display, which simplifies service calls. The required spare parts can be provided immediately based on the error message.

The setpoint adjuster (temperature pre-selection) takes place via a digital Hall Knob, which combines all the advantages of maximum precision and a long service life. Optionally, the temperature can only be preselected by the chef (special key); the temperature would then be preselected behind a service flap. The user or the service personnel may then only switch the heating zones ON/OFF. This reduces incorrect settings and surprises in the process.

The output area is provided with a granite slab (natural stone, material thickness 30mm), a solid, stabilizing substructure avoids breakage of the natural stone.

The substructure is made entirely of CNS steel and is accessible for maintenance purposes with various service flaps. Despite the high weight of the device, the substructure remains level.